top of page

Projects

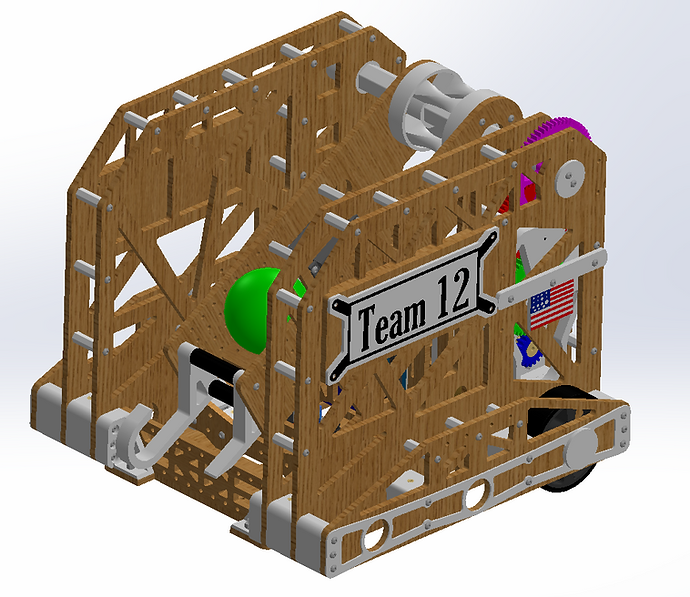

MECH 202 Robot Project

Semester-long project to build a robot to complete a set of tasks in a set amount of time

January - May 25

-

Team of four

-

My role was mechanical design and manufacturing

-

Final assembly in CAD was over 500 components

-

The design was completely from scratch, which included mostly laser-cut and 3D printed components

-

The project included an Arduino, DC motors, motor controllers, a boost converter, a buck converter, and a servo

-

The robot was controlled wirelessly

3DFly

3D printed fly fishing and fly tying accessories

June 24 - current

-

Goal: Practice CAD and rapid prototyping

-

3D-printed in my apartment

-

Designed in SolidWorks

-

Printed out of ABS or ABS-GF

-

Incorporated magnets, elastic cord, heat inserts, and screws into the 3D prints

Renzetti Traveler base workstation:

-

Integrated magnets

-

2 color prints

-

Tight fit around preexisting base

Tabletop magnet organizer:

-

Magnets incorporated into the print during the printing process

-

4 color prints

-

allows for customizable configurations

-

8x6 organizer integrated 48 magnets

-

7x2 organizer integrated 14 magnets

-

Currently 12 different attachments to choose from

Renzetti shaft mounted tool holder:

-

Slides on to most shafts that Renzetti sells

-

No hardware required to hold in place which prevents scratching of shaft

-

Incorporates magnets to hold tools for quick access

Indicator Holder:

-

Hold 4 medium sized indicators

-

floats and light weight

-

openings to allow for drying

-

2 different versions

-

Sliding door w/ magnets

-

elastic cord stretched around opening

-

Rod tube:

-

Printed in 8 pieces

-

Light weight and floats

-

Tight tolerance to the rod to prevent rods from moving

-

Includes magnets for the lid locking

3D printed fly reels

3D printed and created with only components from my apartment

September - December 24

-

Started as MECH 201 design project (fall 2024)

-

Mostly 3D printed but incorporates screw, bearing, and imbedded nuts

-

Click and paw design

-

Light weight w/ minimal parts

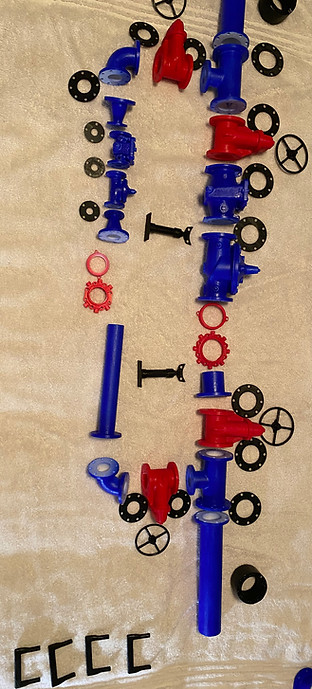

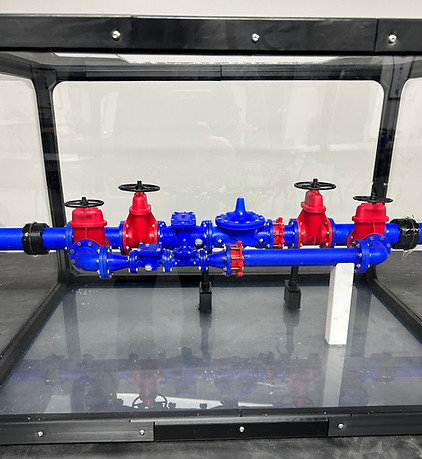

Model of water control assembly

1/10th scale 3D printed model of a water control assembly

March - April 23

-

First converted 2D DXF files of the assembly to 3D SolidWorks assemblies by hand

-

Incorporates real hardware

-

Can be taken apart and put back together

-

Used for teaching

-

The 3D printed pieces were sanded and painted

Battery temperature management system

Temperature management system for 6T prototype battery

June - August 22

-

Uses an Arduino for the electronics

-

Multiple temperature senors

-

Small screen, potentiometer, Relay, and heaters

-

Takes power from battery

Concept lunar rover wheels

-

Made for scaled down RC truck

-

Restriction on materials

-

flexible in design

-

3D printed for prototyping

-

Spring steel for full sized

-

Mostly 3D printed with heat inserts and screws

June - August 21

3D printed articulated swimbaits

-

Started as high school design project

-

3D printed, sanded, air brushed, and epoxied

-

Molds 3D printed and injection molded with old soft plastics

-

Started with hand drawn pictures and designed in SolidWorks

-

3D printed with metal pin for the motion

April 19 - April 22

Jon boat build

-

Started will and old jon boat and ripped it down to the hull

-

Repaired leaks & holes

-

Created a frame and desk from wood

-

carpet for the desking and lighting throughout

-

Rewired whole boat

-

Completed normal maintenance on the 40 HP outboard

March - May 18

bottom of page